Different types of extractors can help to clear up anything you disperse. However, it is just as important to make sure you have dust filter bags that fit the equipment you are using. you need to make sure you are using the right dust extractors for your workplace and your needs.

Finding the best dust extraction filter bags is as simple as looking for a trusted brand. While it may not seem like it on the surface, dust can be deadly! Therefore, dust extractor filter bags are vitally important. It’s also crucial that you change any dust filter bags you use regularly. Harmful dust must always be safely cleaned and removed from any areas where it is likely to be breathed back in. Our systems are designed to suit your specific requirements by our qualified personnel

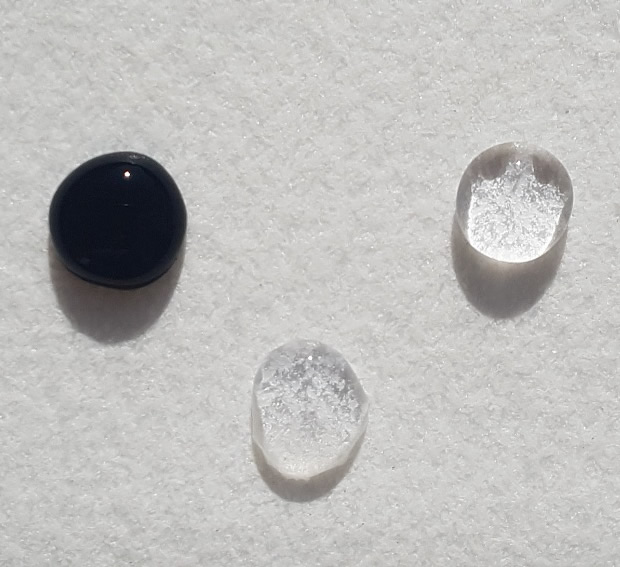

The oil and water repellent (fiber) finish of a fluorocarbon resin basis, has been conceived for separation of wet, oily and tacky dusts.

Even for non continuous processes, where the temperature falls below the dew point, the oil and water repellent finish prevents the uptake of moisture by the needle felt, thus reducing the danger of excessive dust deposits and caking.

The PTFE has a micropore surface coating on PTFE-basis showing marked advantages for the separation of agglomerating, strongly adhesive, or tacky dusts.

The advantages of the PTFE coating are due to two essential effects: The filter-active coating begins to separate the dust on the surface area. In addition, the anti-adhesive PTFE-surface area reduces the adhesive properties of the filter medium and dust cake. This facilitates cleanability and so premature blocking of the filter is avoided.

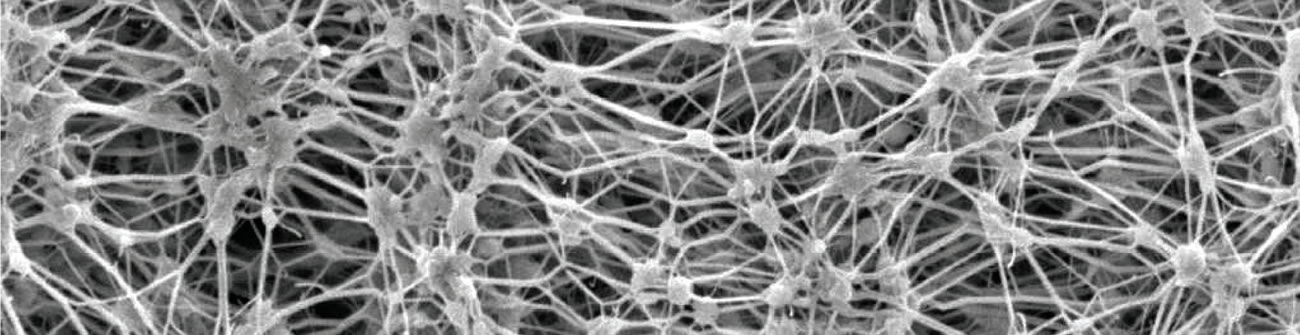

Tetratex® Release is a surface filtration PTFE membrane, laminated onto a variety of substrates for pulse jet baghouse applications, providing the flexibility to meet your needs. It acts as a primary dust cake requiring no precoat before or during operation. Tetratex® Release is thermally bonded onto the following needlefelts – Polyester/Epitropic anti-static, Polyester, Acrylic, P-84®, polypropylrne, PPS, Aramid, on felts and wovens. By limiting fine particle penetration, Tetratex® Release delivers high capture rates, whilst preserving the filter substrate’s integrity and maintaining optimum airflow at a reduced pressure drop. Resulting in higher air-to-cloth ratio, extended bag life and energy savings. A Low Cost PTFE Membrane with Unrivalled Dust Cake Release Properties Tetratex® Release membrane is highly permeable and suitable for use where dust particles are primarily larger than 3 microns.

Tetratex® Release membrane offers enhanced needlefelt surface finish, providing higher efficiency and superior dust cake release than other coated medias. Tetratex® Release is manufactured from PTFE Fluropolymer resin. It is a chemically inert material that virtually eliminates concerns regarding fiber contamination. Tetratex® Release membrane is thermally stable up to 287°C maintaining performance at high temperatures. Donaldson Membranes, is a leading worldwide manufacturer of expanded microporous PTFE membranes, Tetratex® films and laminates. A technology- driven company committed to satisfying customer needs through innovative research and development with production & sales offices located throughout Europe , America and Asia. Tetratex® Release Features and Benefits Superior collection efficiency compared to PTFE coated products a range of substrates -Polyester, Anti-Static Polyester, Acrylic and Aramid Tetratex®, etc Release results in near zero emissions for particles larger than 3 microns Reduced cleaning Tetratex® Release is a low cost, value for money alternative to conventional coated needlefelts.

With today's technology, all the type's of dust can be collect with special filter cloths containing metal fibers within the structure of the cloth, and this metal fibers are mostly made from Stainless Steel, Copper or Bronze. The thing we call STATIC ELECTRICITY is actually an imbalance in the amounts of positive and negative charges in the surface of an object.

It's only the imbalance of opposite charges which is important, not whether it's moving or static. In fact, the charge-imbalance can flow along as an electric current and that creates spark.

Companies they produce Fertilizer, wood work, flour mills or in pharmaceutical industry, or any other filtering dust is highly flammable with the pressure and the distance of the dust particles the one next to the other the only think to get in danger the personnel and the plant is a single spark.